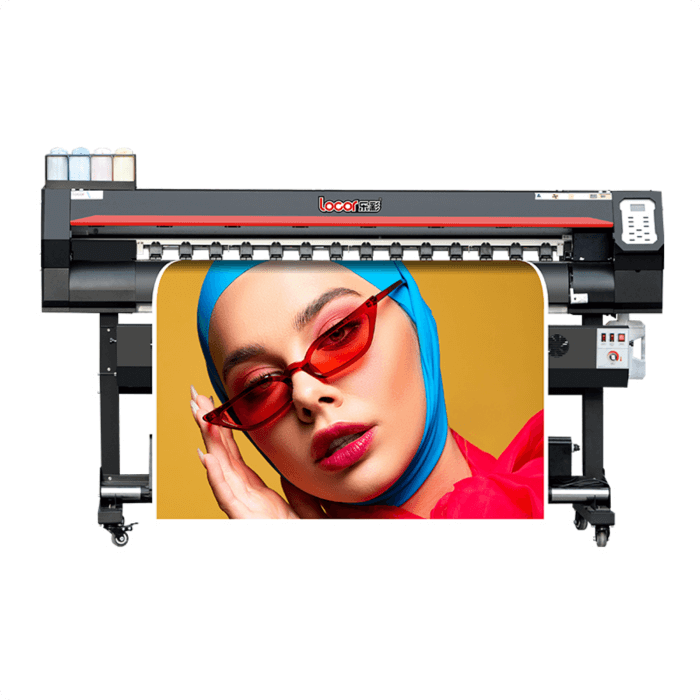

Application

Features

- New automatic production scheme, high strength industrial design structure, up to 10,000 meters of feeding and receiving system, fully realize unattended automatic production scheme, so that productivity is further improved.

- High strength frame — side large steel plate link, the stability of the whole machine is higher. It can realize ten thousand meters of paper shaft, reduce the frequency of media replacement, greatly save time and manpower.

- Weighted rubber roller — more uniform feeding paper, high precision output, and it is not easy to appear phenomenon of pressure roller printing and paper wrinkling.

- Feeding and receiving system — effectively solve the step deviation and speed change caused by different material diameters and ensure that the materials are collected neatly,

- Front and the bottom are drying at the same time, which improves the drying efficiency and saves a lot of time.

Details

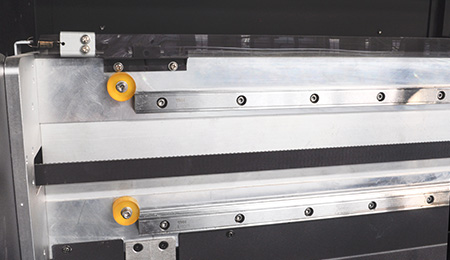

Dual Guide Rails

Equipped with THK silent dual guide rails, ensuring smoother vertical high-speed operation and higher printing precision.

High-Power Double Dryer

Equipped with dual dryers to speed up ink drying, ensuring smooth paper feeding and collection for high-speed printing.

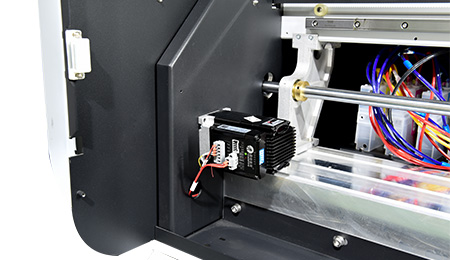

Linear Motor

The use of high-quality linear motors greatly increases the printing speed and improves the stability of printing to ensure high-quality continuous output.

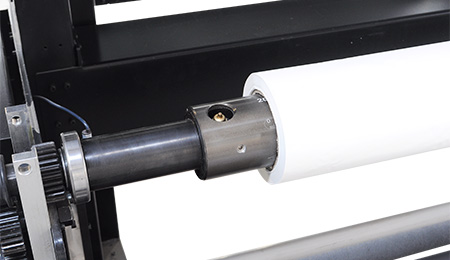

Air Expanding Shaft

The front and rear rewinding and unwinding devices are equipped with air expansion shafts and more stable conveying and feeding devices.

Specifications

| Product Model | LC-2608 |

| Printhe ad Type | Epson i3200-A1 |

| Number of Printhead | 8 |

| Printhe ad Height | 2-3mm |

| Printhead Cleaning | Fully automatic cleaning with anti-clogging,flash spraying, and automatic moisturizing functions |

| Ink Type | Dye-sublimation ink |

| Ink Color | Four colors(C/M/Y/K) |

| Ink Cartridge Capacity | 5000ml per color |

| Ink Supply Method | Negative pressure continuous ink supply system |

| Printing Width | 2600mm |

| Media | Dye sublimation paper |

| Maximum Roll Weight | Kilometer paperweight(optional) |

| Take-up Device | Dual infrared heating with external drying fan |

| Heating System | Three-Stage Embedded Constant Temperature Heating System (Front, Middle, Rear) |

| External Drying Configuration | Negative pressure continuous ink supplysystem |

| Operation Language | Chinese/English |

| Computer System | Win11/Win10 |

| Operating Environment | Temperature range 18°C-25*C;Humidity range 35%-65% Rh |

| Printing Interface | USB |

| RIP Software | Maintop/Photoprint/Wasatch |

| Power Parameters | AC-220V, 50Hz/60Hz |

| Power(W) | Standbypower 64W,maximum power 7800W |

| Noise Level | Standby <32dB,operating s65dB |

| Machine Dimensions | 4430mmx1235mmx1850mm(LxWxH) |

| Machine Net Weight | Air shaft, automatic winding and unwinding system |

Get a Quote Now

Related Video

Factory Strength

A Powerful Printer Manufacturer From China Since 2003

20+ Years Printer Factory

Technical support

Support methods usually include telephone support, online customer service, remote support, etc.

Printing supplies

Locor manufacturers or authorized dealers usually provide corresponding inks, powder films and other consumables.

Spare parts

We usually provide customers with original accessories (such as boards, ink sacs, motors, etc.).

Related Products