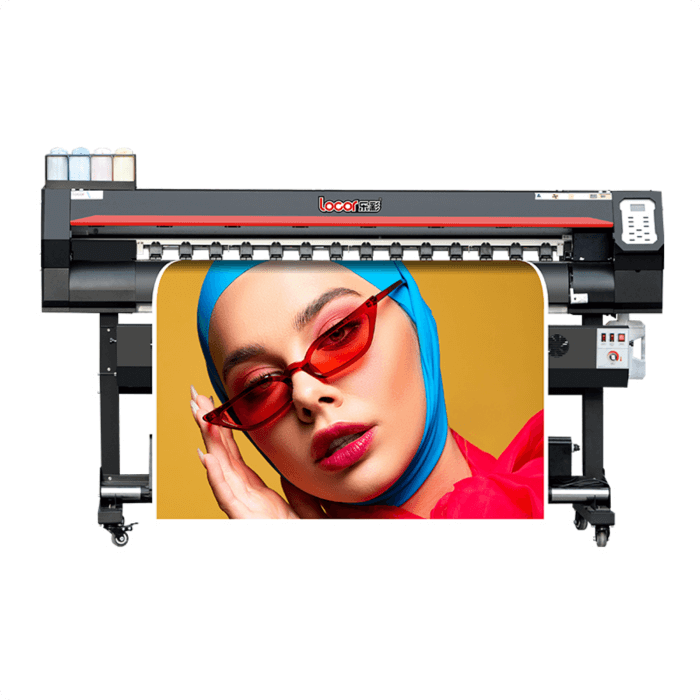

Application

Description

Sublimation Textile Printer is a device specially used for textile printing, which mainly uses thermal sublimation technology to transfer patterns to fabrics. With its high quality, durability and environmental protection advantages, it is widely used in the field of textile printing, especially suitable for personalized customization and large-scale production.

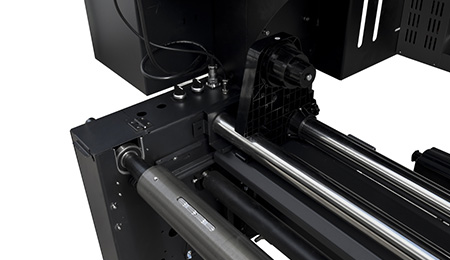

Imported guide rail

Using THK silent rails and equipped with double sliders to ensure smoother operation of carriage, higher printing accuracy.

Printhead anti-collision device

The three anti-collision devices are on both sides of the trolley.

Ecosolvent drying system

Heating temperature and fans speed can be adjusted accordingly. It is ideal for printing roll to roll with heavy ink like backlit or white. It also helps to dry up ink for immediate lamination.

Air Shaft Taking Up System

An air shaft take up system maintains controlled tension, prevents material slack and wrinkles. It is essential for consistent media feeding and facilitates the winding of material onto the take-up roll and minimizing material waste.

Automatic paper-detecting device

The printing platform device has automatic paper-detecting device, automatic detection of printing media print end, make printer more smarter.

Intelligent control panel

Simplified operation can quickly adjust printing operations, improve work efficiency!

Specification

| Product Model | Deluxejet3200 |

| Printhead Type | 13200-A1/E1 |

| Number of Printhead | 4 |

| Printhead Height | 2-3mm |

| Printhead Cleaning | Fully automatic cleaning with anti-clogging,flash spraying, and automatic moisturizing functions |

| Ink Type | Eco-Solvent/Water-Based/Sublimation Inks |

| Ink Color | Four colors(C/M/Y/K/) |

| Ink Cartridge Capacity | 3000ml per color |

| Ink Supply Method | Negative pressure continuous ink supply system |

| Printing Width | 3200mm/1500mmx2 |

| Media | Photo Paper/PP Paper/ Canvas / Rice Paper / Vehicle Vinyl / Heat Transfer Paper, and More. |

| Maximum Roll Weight | <100Kg |

| Take-up Device | Fully Automatic Winding and Unwinding (Standard) |

| Heating System | Three-Stage Embedded Constant Temperature Heating System(Front, Middle, Back) |

| External Drying Configuration | Dual infrared heating with external drying fan |

| Operation Language | Chinese/English |

| Computer System | Win11/Win10 |

| Working Environment | Temperature range 18*C-25℃; Humidity range 35%-65% Rh |

| Printing Interface | USB |

| RIP Software | Maintop/Photoprint |

| Power Parameters | AC-220V,50Hz/60Hz |

| Power (W) | Standby power 2000W, maximum power 6500W |

| Noise Level | Standby <32dB, operating s65 dB |

| Machine Dimensions | 4610*990*1778mm(L*W*H) |

| Machine Weight | 850kg |

| Package Dimensions | 4910*1120*1150mm(L*W*H) |

Get a Quote Now

Related Video

Factory Strength

A Powerful Printer Manufacturer From China Since 2003

20+ Years Printer Factory

Technical support

Support methods usually include telephone support, online customer service, remote support, etc.

Printing supplies

Locor manufacturers or authorized dealers usually provide corresponding inks, powder films and other consumables.

Spare parts

We usually provide customers with original accessories (such as boards, ink sacs, motors, etc.).

Related Products