The advertising industry is well aware of the versatile and widely used UV printers. By 2024, the industry has developed UV flatbed printers capable of printing on wood, glass, plastic, steel, ceramics, cardboard, corrugated paper, acrylic, and other materials. We are constantly amazed by the realistic 3D embossed effects produced by UV printing. By 2025, we will be able to apply this artistic effect to the textile industry through TPU materials.

What does TPU UV printing mean?

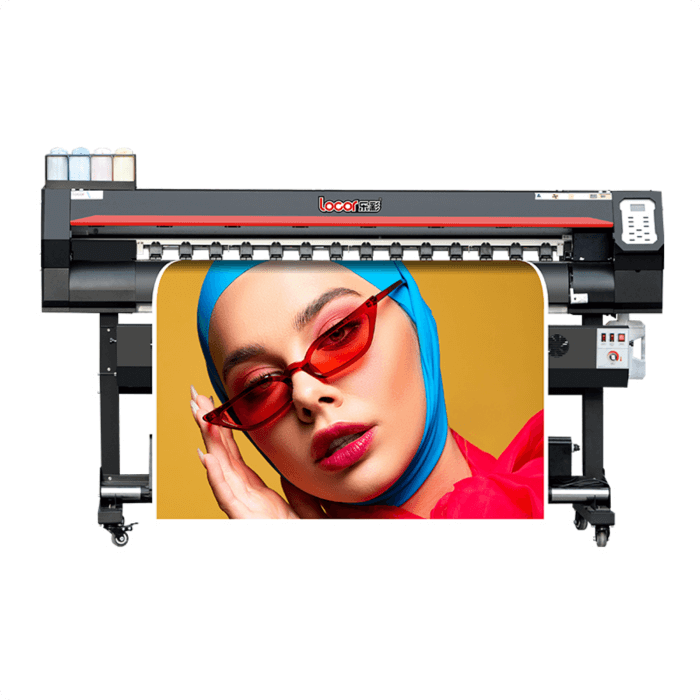

Printing directly onto TPU material using a UV flatbed printer. No special processing or plate making is required, and the product dries instantly.

How to perform TPU UV printing?

- Design your design.

- Place the TPU film on a UV flatbed printer for printing.

- Use a die-cutter to automatically cut the design in batches.

- Adjust the temperature of the hot press and transfer the printed TPU material to the textile using a heat press.

3D embossed effects

3D embossed labels bring surprises

Designs printed with TPU UV not only create raised, textured images like silicone stickers, but also simulate three-dimensional effects like leather textures, metal carvings, and fabric textures. We’ve already received orders for samples and machines from the apparel industry.

TPU UV printing offers many possibilities in the future

Customized TPU phone case designs

Surface designs for wearable devices (such as smart bracelets)

TPU shoe materials (customized designs and logos)

Creative products (soft keychains, card holders, etc.)